Applications of 132kV Composite Suspension Insulators

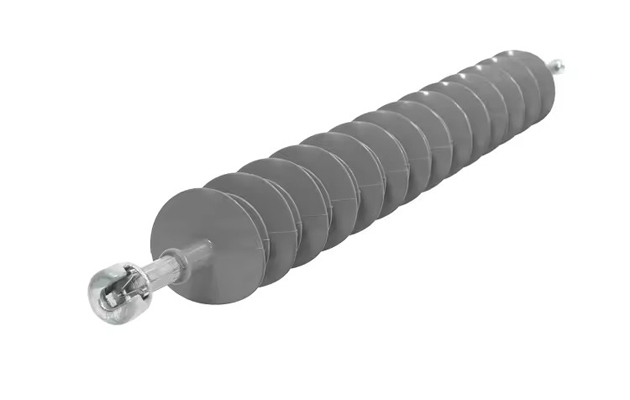

132kV composite suspension insulators are primarily used in high-voltage transmission lines to support conductors while electrically isolating them from the ground or supporting structures. Their composite construction, typically consisting of a fiberglass core covered with silicone rubber sheds, provides excellent electrical insulation and mechanical strength. This makes them ideal for use in areas with harsh environmental conditions, such as coastal regions with high salt contamination, industrial areas with pollution, and regions prone to extreme weather.

The composite insulators lightweight nature reduces the load on supporting structures, making them easier to install and maintain compared to traditional porcelain or glass insulators. Furthermore, their hydrophobic properties help prevent the formation of conductive water films, reducing the risk of flashovers and improving overall system reliability.

Fittings for 132kV Composite Suspension Insulators

To ensure proper installation and performance, 132kV composite suspension insulators are typically equipped with a range of fittings. These fittings include:

Ball and Socket Links: These are commonly used to connect the insulator to the tower or pole. The ball and socket design allows for flexibility and ease of installation, accommodating slight misalignments and reducing mechanical stress on the insulator.

Yoke Plates: Yoke plates are used to connect the insulator to the conductor. They provide a secure attachment point and distribute the mechanical load evenly across the insulator. Yoke plates are often made of high-strength steel or aluminum to withstand the tension and weight of the conductor.

Clevis and Tongue Links: These fittings are used in situations where a more rigid connection is required. The clevis and tongue design provides a strong, stable connection, making it suitable for applications with high mechanical loads.

Corona Rings: Corona rings are sometimes installed at the high-voltage end of the insulator to control the electric field distribution and reduce the risk of corona discharge. This is particularly important in high-voltage applications where corona discharge can lead to energy loss and equipment damage.

Grading Rings: Grading rings are used to improve the voltage distribution along the insulator string, reducing the risk of flashovers and improving the overall performance of the insulator.

Conclusion

132kV composite suspension insulators are a critical component in modern high-voltage transmission systems, offering excellent electrical and mechanical performance in a wide range of environmental conditions. This type insulator’s lightweight design, combined with advanced materials and fittings, makes them a reliable choice for hanging conductors and ensuring the safe and efficient operation of power networks. With the right fittings, such as ball and socket links, yoke plates, and corona rings, these insulators can be tailored to meet the specific needs of any high-voltage application.