Composite insulators are also called polymer insulators. Their insulating parts are composed of fiber glass core rods (or core tubes) and organic material sheaths and sheds. They are characterized by small size, light weight, high tensile strength, and excellent anti-pollution flashover performance. However, their anti-aging ability is not as good as that of porcelain and glass insulators.

Composite insulators include: long rod suspension insulators, crossarm insulators, post insulators, and hollow insulators (i.e. composite bushings). Composite bushings can replace porcelain bushings used in a variety of power equipment, such as mutual inductors, lightning arresters, circuit breakers, capacitor bushings, and cable terminals.

Compared with porcelain bushings, composite insulators are small in size, light in weight, easy to install and maintain in time; have high mechanical strength and are not easy to break; have excellent seismic resistance and good pollution resistance; have fast production cycles, high quality stability, and can also avoid damage caused by explosions.

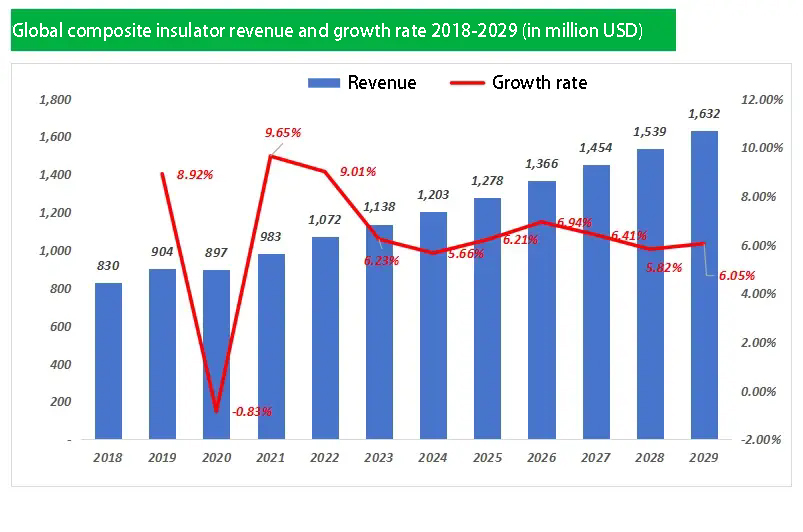

overall scale in 2018-2029 for global composite insulator industry

overall scale in 2018-2029 for global composite insulator industry

In 2023, the global composite insulator market will have a turnover of approximately USD 1,138 million and is expected to reach USD 1,632 million by 2029. We expect the global turnover to grow at 6.29% from 2024 to 2029. The continued growth of power construction investment is the main driving factor for the growth of the composite insulator market.

The main global composite insulator manufacturers include Siemens, Hitachi, PFISTERER, TE Connectivity, etc. In 2023, Siemens is the world’s largest composite insulator manufacturer, with composite insulator sales reaching US$192.54 million, accounting for 16.91% of the global composite insulator market.

At present, the composite insulator market is mainly divided into three types: ultra-high voltage, power transmission and distribution, and electrified railway composite insulators. Among them, power transmission and distribution composite insulators are the main type. In 2023, the global power transmission and distribution composite insulator turnover was US$694.99 million, accounting for approximately 61.05% of the global market.

More and more people in the world realize that the application of composite materials in power equipment will be a trend in the future, because composite materials are essential to the safe operation of power grids. In the North American and European markets, composite insulators for substations have gradually become a development trend in the insulator market. Among them, the French RTE company plans to remove all porcelain insulators used for circuit breakers from substations by 2030 for safety reasons (explosion risk). Insulators in more than 3500 substations need to be replaced with composite insulators. Customers are increasingly pursuing highly reliable, low (full life cycle) cost, short delivery time, low energy consumption, and greener products. The composite insulator market has broad prospects.