Rated voltage:10kv, 22kv, 33kv, 66kv, 110kv, 220kv, 330kv, 400kv, 500kv

End fitting type: cap, flange, customized fitting...

International Standard: IEC61952, IEC62217, ANSI 29.11, ANSI 29.19

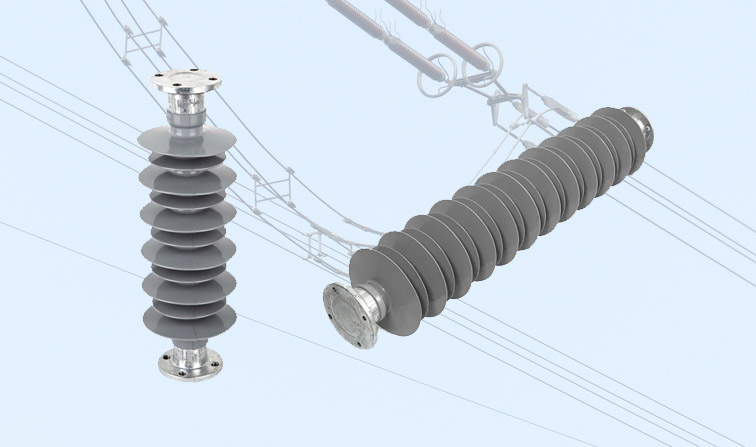

Material: HTV silicone rubber, fiberglass rod, forged steel end fittings

Composite post insulators are made of a fiberglass-reinforced resin matrix core, polymeric weathersheds and metal end fittings. The insulators are intended for use in outdoor substation applications or apparatus.

Mechanical loading of composite post type insulator design can be compression, cantilever, tensile and/or torsion, depending on the application. End fitting type and bolt circle dimensions can be critical for the replacing of current post insulators on line.

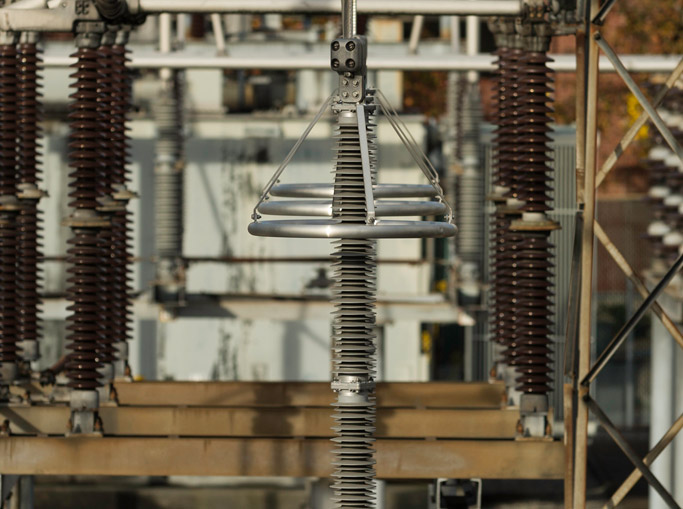

Composite station post insulators less than 110kv can be one stack, 220kv is normally 2 stacks, and upto 330kv is normally 3 or more stacks which are assembled together. The core size diameter is designed to meet certain mechanical loading, the thicker, the stronger, but it is also more expensive. To choose suitable fiberglass core size is important for better design of post insulators.

Essential parameters for composite post insulators:

>System or rated voltage

>creepage distance

>dry acring distance if important

>total height

>lightning impulse withstand voltage

>specified cantilever load

>tension load, compression load, torsion load if required

>end fitting types

>end fitting assembling dimensions

Except the above, other special requirements by the end user are needed.

Packing: cartons or wooden cases with pallet, suitable for seafreight or airfreight.

Production cycle: 30-45 days